Brobygrafiska received a banded anilox donation

publication date: 2016/12/07

The Brobygrafiska school in Sweden received a top-notch donation

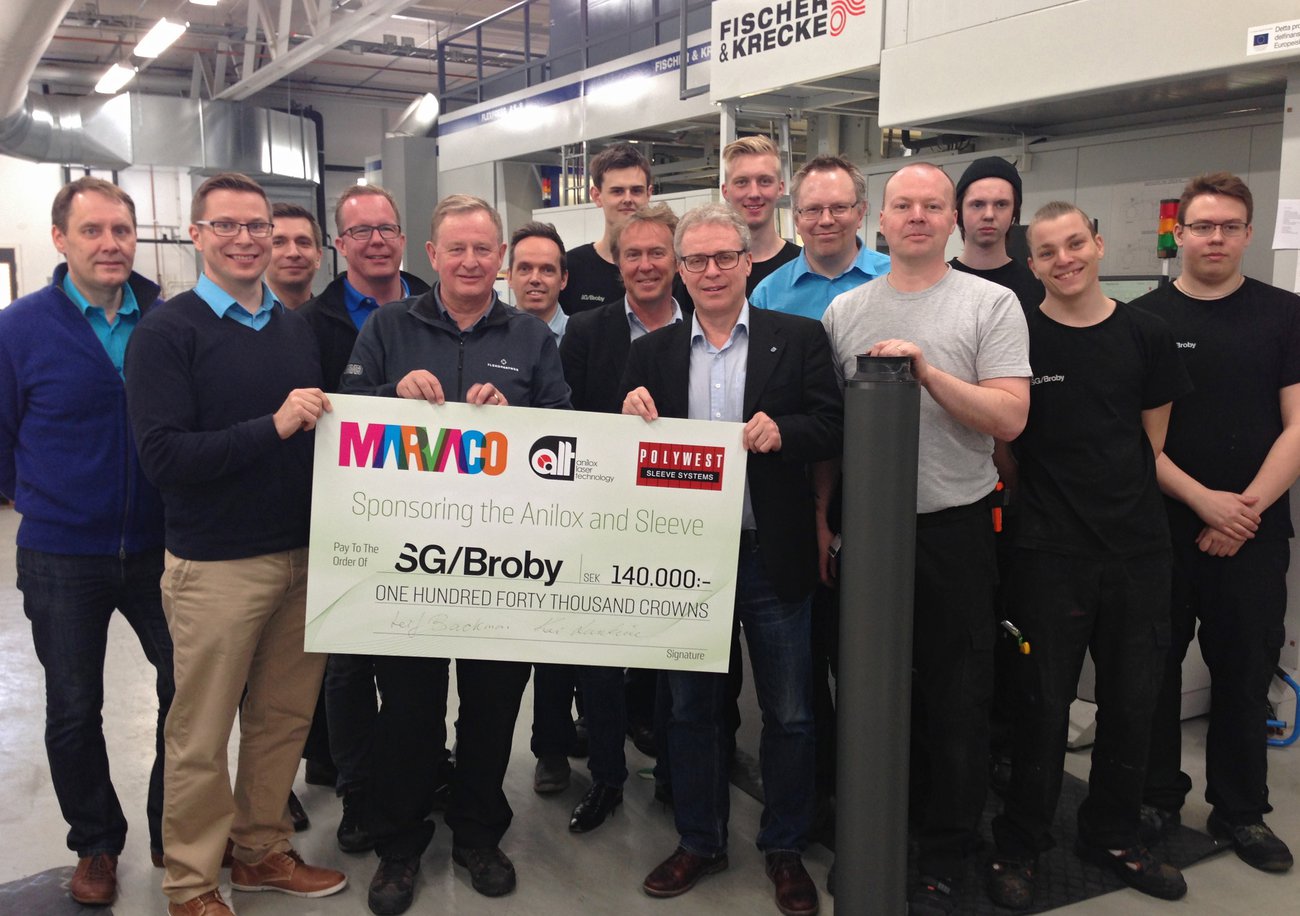

Marvaco, together with Anilox Laser Technologies (ALT) and Polywest, have made a donation to flexo printing in the Brobygrafiska school in Sunne, Sweden. The donated state-of-the-art banded anilox roller is designed to give information about the development of ultra-high definition flexo printing, e.g. 100 lpcm (254 lpi).

The banded anilox roller benefits the printers, ink manufacturers, plate producers and material suppliers in their development work. The anilox covers different kinds of traditional and modern engravings from 420 to 600 lpcm (1066–1524 lpi) and volumes from 3.5 to 2.0 ccm (2.26–1.29 bcm).

“This is a large investment for the common good, and we are happy to cooperate and offer the most modern test setup for the school,” says Kai Lankinen, CEO of Marvaco.

Simultaneously with the banded anilox, a set of Twinlock sleeves in different hardness were also donated to the Brobygrafiska by Polymount. The donations make it easy for flexo printers to select the best setup for their own purposes.

The Brobygrafiska school offers an optimal place for the students and the industry professionals to meet and it educates highly skilled work resources for the graphic industry. The state-of-the-art facility is already equipped with the most modern prepress and printing technology – it is probably the best-equipped graphical school in the world. The school even has a full-sized 8-colour gearless Bobst F&K 6S flexo printing machine on-site for students and companies, to be used for education and test runs.

“This is a good example of how the Brobygrafiska school is on the top of the development in the industry and connected into the daily working life,” says Per Branzén, the Operation Manager of the Brobygrafiska, and adds that the students of the school are very well placed around the world in various positions across the graphical packaging industry.

The setup in the school offers a very good base to experiment and develop flexo printing to break the traditional barriers. “We can already use the knowledge from these learnings in our Full HD and Expanded Gamut Printing (EGP) projects with our partners,” states Lankinen. Marvaco’s premises in Sunne are just few hundred meters away from the Brobygrafiska, which makes collaboration with the school and its partners easy and effective.

For further information, please contact:

kai.lankinen@marvaco.fi